The Ultimate Guide to Bleeding Air from Your Diesel Fuel System

Share

When it comes to diesel engines, proper maintenance is crucial for optimal performance. One common issue that diesel engine owners may encounter is air in the fuel system. Air can enter the fuel system through various means, such as a faulty fuel filter, a loose connection, or even during routine maintenance. If left unaddressed, air in the fuel system can lead to decreased engine performance, rough idling, and even engine damage. In this ultimate guide, we will walk you through the process of bleeding air from your diesel fuel system, ensuring that your engine runs smoothly and efficiently.

What is air in the fuel system and why is it a problem?

Air in the fuel system refers to the presence of air bubbles or pockets within the fuel lines or fuel injectors. This can disrupt the flow of fuel to the engine, leading to a lean fuel mixture and poor combustion. As a result, the engine may experience a loss of power, misfires, or even stalling. Additionally, air in the fuel system can cause damage to the fuel injectors, which are responsible for delivering fuel to the combustion chamber.

Step-by-step guide to bleeding air from your diesel fuel system

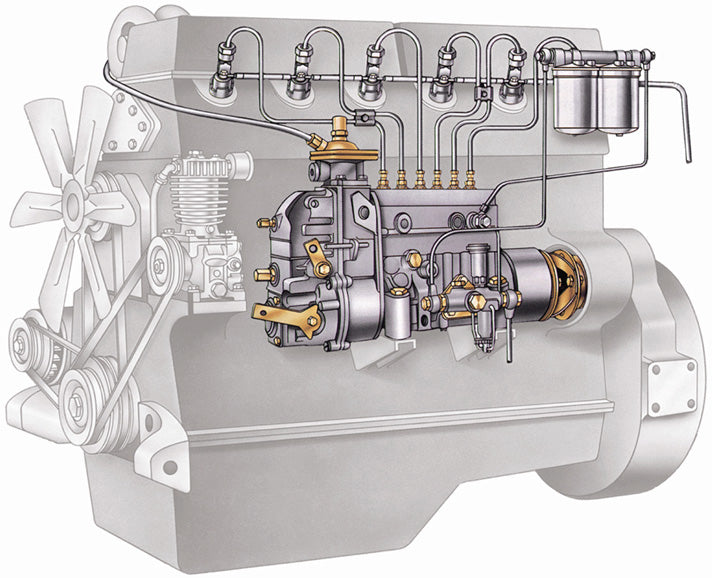

1. Identify the location of the fuel system components: Start by locating the fuel filter, fuel pump, and fuel injectors. Refer to your vehicle's manual if you are unsure about their exact location.

2. Turn off the engine: Before starting the bleeding process, ensure that the engine is turned off to prevent any accidents or injuries.

3. Locate the fuel bleed screw: The fuel bleed screw is typically located on the fuel filter or the fuel pump. It is used to release air trapped in the fuel system.

4. Prepare a container: Place a container or a rag beneath the fuel bleed screw to catch any fuel that may be released during the bleeding process.

5. Loosen the fuel bleed screw: Using a wrench or a screwdriver, carefully loosen the fuel bleed screw. Be cautious as fuel may start to flow out.

6. Bleed the air: Once the fuel bleed screw is loosened, air bubbles may start to escape along with the fuel. Allow the air to bleed out until a steady stream of fuel without any air bubbles is observed.

7. Tighten the fuel bleed screw: Once the air is bled from the system, tighten the fuel bleed screw securely to prevent any fuel leaks.

8. Repeat the process: Repeat steps 5 to 7 for each fuel injector, starting from the one closest to the fuel pump and moving towards the engine.

9. Start the engine: Once you have bled the air from all the fuel injectors, start the engine and check for any signs of air in the fuel system. If the engine runs smoothly without any issues, you have successfully bled the air from your diesel fuel system.

Conclusion

Bleeding air from your diesel fuel system is an essential maintenance task that should not be overlooked. By following the step-by-step guide outlined in this ultimate guide, you can ensure that your diesel engine operates at its best. Remember to exercise caution and refer to your vehicle's manual for specific instructions. With a properly functioning fuel system, you can enjoy the benefits of a powerful and efficient diesel engine.

1 comment

I have a MF 390 85 HP tractor with Perkins engine and a real pain to bleed after change. Lift pump seems so feeble it takes MINUTES to refill filter and body to the point battery is depleted before system is primed. The system also incorporates automatic passive air bleed, a facet upon which I do not depend when manually bleeding.